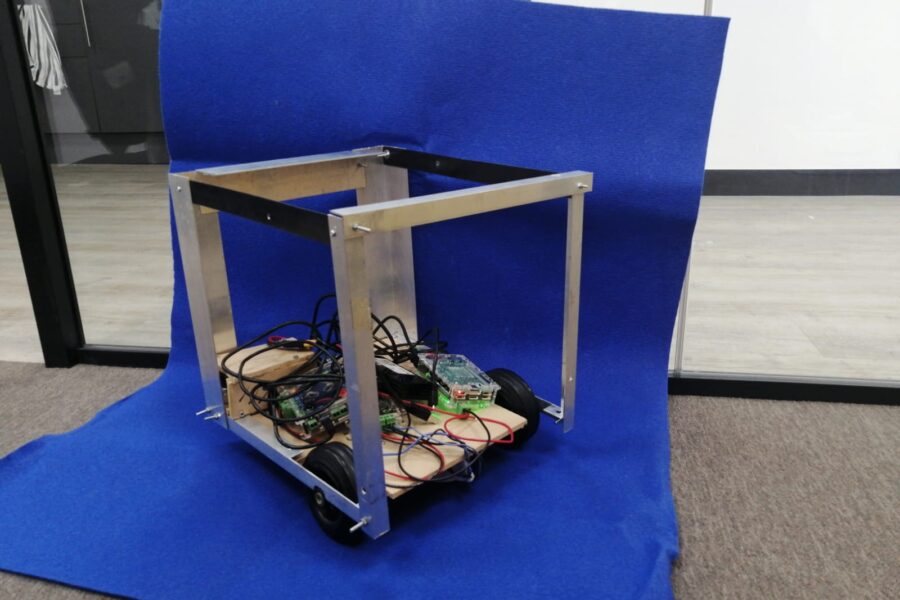

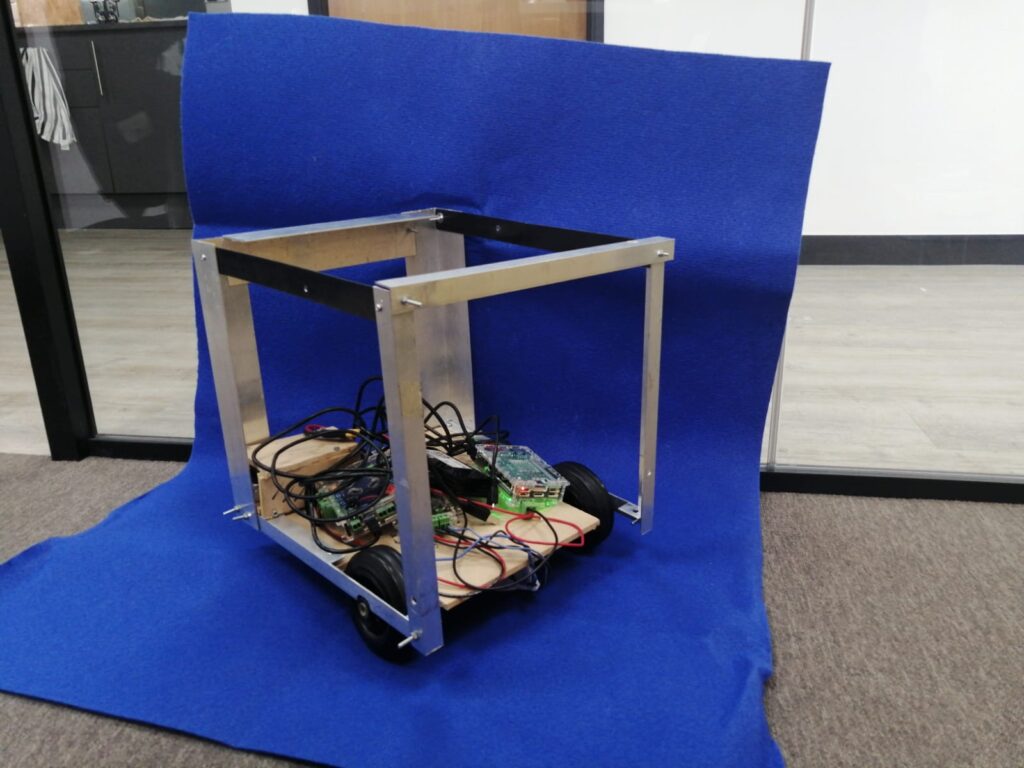

As part of team HZW for this year’s competition, I’ve been getting stuck into building the hardware of our robot, taking a more challenging path than I would’ve liked to (so far, it’s a two-person team of I and me!). The first competition event was on a Saturday in Horsham, so I panicked and thanks to our fabulous DT department, threw this frame and wheels together the day before we needed it. Turns out, the other teams at the “Tech Day” were more or less at a planning stage, so we were way ahead of the competition.

A team from Westminster arrived empty handed, and spent the day conjuring sabotage plans and winner algorithms on their whiteboard while we installed the Raspberry Pi 4 “Brain Board” and hooked up the motors. Although that being said, team RGS managed to complete all three of the preparation challenges on the same day of Kickstart, which was a shocker! By the end of the day we had our robot spinning around and shooting down the hallway. We had some problems to fix, and came home with a plan.

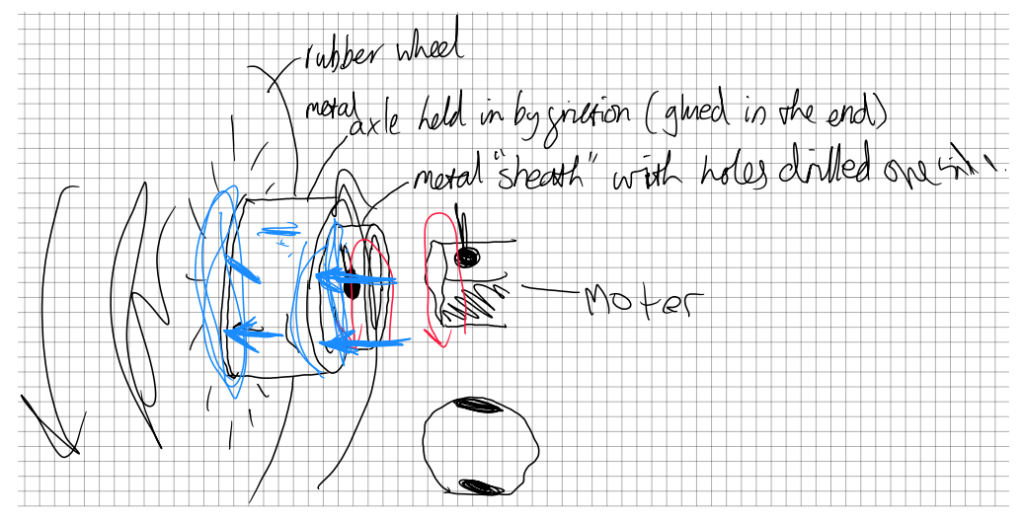

Some of the issues we had were quite annoying though. Since the wheels weren’t fitted correctly with a slip-fit sort of metal dowel or split-pin, the actual wheel part would take a couple of seconds to spin up. You see, the motor got spinning instantly and the wheels wouldn’t be able to catch up. This meant the robot would take time to build speed and also somewhat “coast” as the motors stopped spinning. The videos above you can see it better, as the robot can’t quite drive in a straight line. And a crude diagram below to confuse you.

Anyway we’ve since fixed the problem by drilling straight through the metal sheath and metal axle and bolting them through the motor shaft.

However, I drilled one of the motor’s holes too big, so one of the wheels has a lot more wiggle than the other, which you can see me explain in the video above. So now we’ve got to epoxy the hole and re-drill it smaller, which shouldn’t be too hard to do…